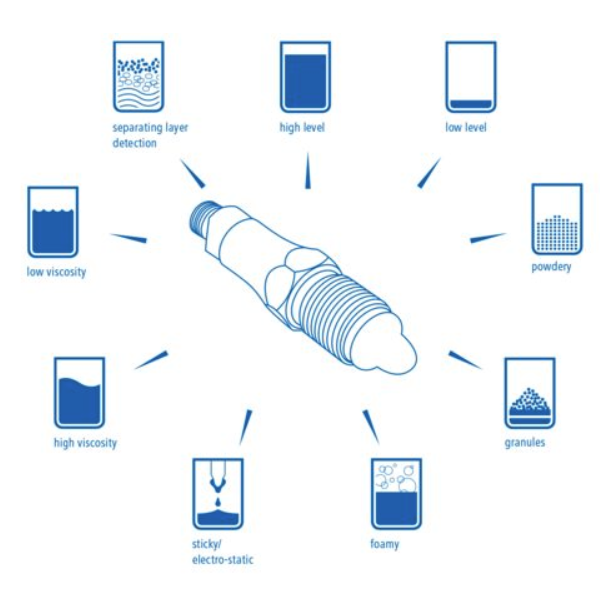

Sensor requirements are just as diverse as the media sensors are supposed to detect. Applications vary from dry running protection at pumps to reliable overflow or leak monitoring on to selective media detection with suppression of foam or separating layers. Baumer is first to meet all these requirements with one single sensor technology. No matter whether it comes to bulk goods, powders, liquids , foam, or sticky or viscous media. One or more switching points will reliably monitor point levels of fluids in tanks, containers or pipes.

Detection of foam and separating layers

In certain processes, the medium occurs in different states (e.g. liquid or foam). These can be selectively detected or masking (e.g. foam layer). A clear distinction is also possible between the media of one separating layer (e.g. oil on water).

Reliability with viscous media

In the processing of sticky and viscous media, viscosity and adhesion properties play a large part. For CleverLevel adhering remains do not represent a challenge. It always switches reliably and is maintenance-free.

Process safety with bulk goods

Bulk goods come in many different grain sizes in a large number of applications. Vibrating forks pose a risk of material deposition or jamming of these media, which triggers incorrect messages. CleverLevel, on the other hand, is suitable for all media. Unwanted production downtime are a thing of the past.